-

Pre-Commissioning

- Chemical Cleaning

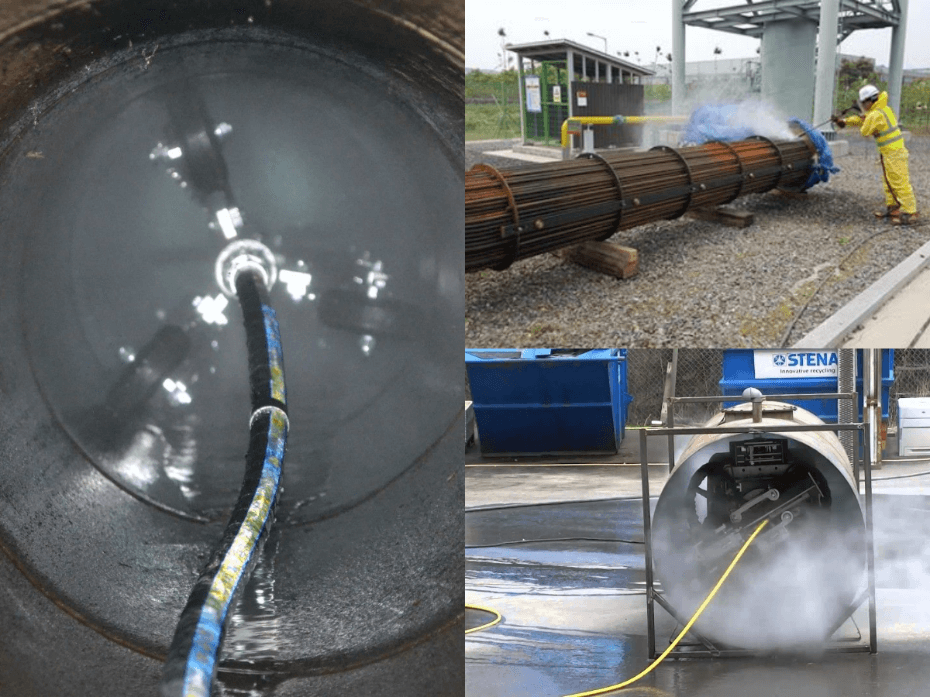

- Hot Oil Flushing

- Pressure Testing

- High Pressure Cleaning

- Hose Management

- Nitrogen purging

- Flange Management

- Video Inspection

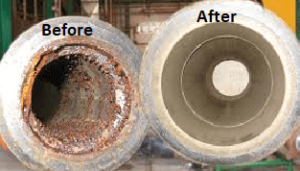

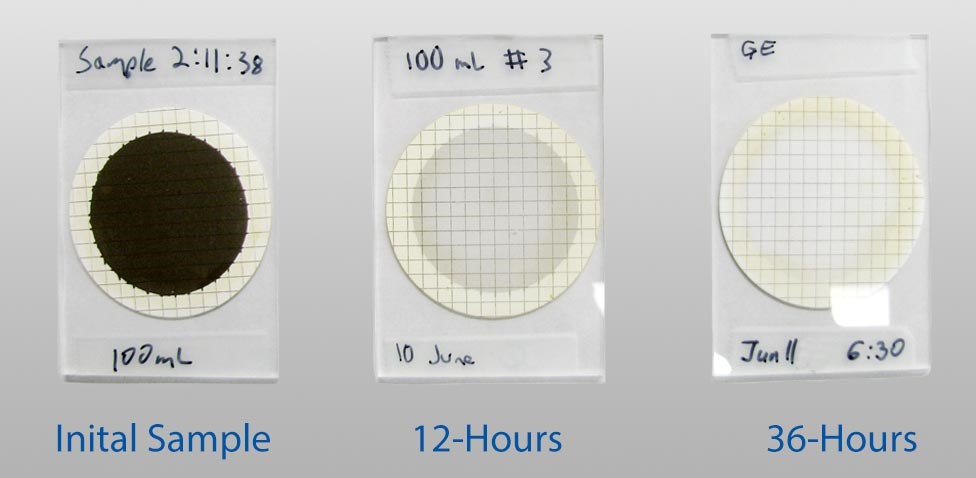

Chemical Cleaning

Our services include two major categories of chemical cleaning are pre-operational chemical cleaning—part of pre-commissioning or commissioning activities—and post-operational or maintenance chemical cleaning—part of regular shut down work

We offer two methods for cleaning :

- Fill and Soak Method

- Fill and Circulation Method

- Fill and Soak Method

- Fill and Circulation Method

Benefits:

- Increased pipeline life in years

- Reduction of pipeline maintenance

- Saving on corrosion inhibitors

- Maintained product purity

- Reduce friction and increases pipeline flow efficiency

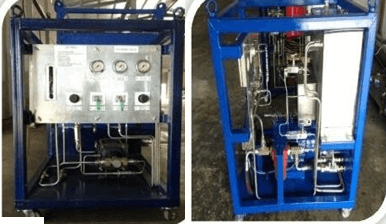

Hot-Oil Flushing

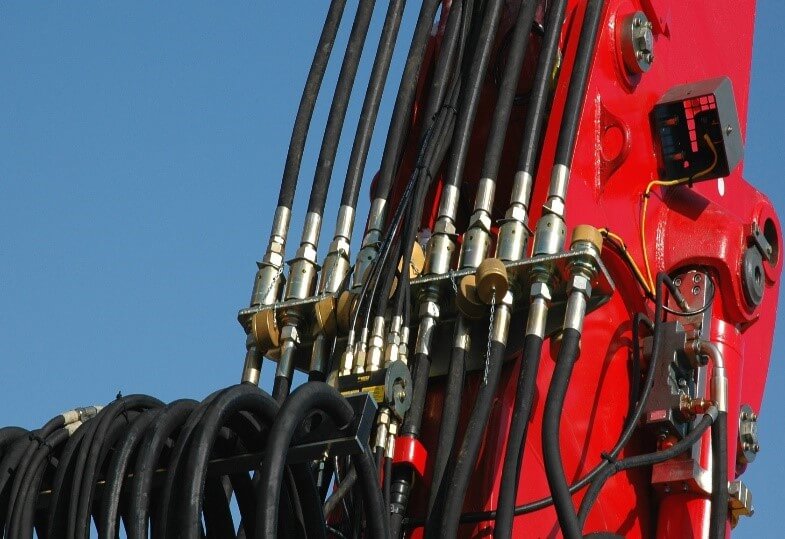

Our services to remove harmful contaminants such as water, rust, loose scale, weld slag, sand and dirt’s from the critical internal components of hydraulic and lube oil system. Our Hot Oil flushing services operates on the principle of turbulent flow, which requires the understanding and skill of trained technician to ensure that significant damage doesn’t not occur during the process.

Our flushing systems are equipped with high efficiency filter elements to achieve very low particle counts quickly.

Benefits:

- Free from contaminants and debris

- Long life of machinery, lubrication and hydraulic systems

- Preventing premature component failure

Pressure Testing

We provide pressure test methods to a variety of industry standard. Pressure Test is to ensure the safety, reliability and leak tightness of pressure systems that is required for a new pressure system before use or an existing pressure system after repair or alteration. The pressure test can be performed as two methods.

Hydrostatic and Pneumatic. A Hydrostatic test is performed by using water as the test medium, whereas a Pneumatic test uses air, nitrogen, or any non-flammable and non-toxic gas. Pressure tests must always be performed under controlled conditions, following an approved test plan, and documented in a test record. A single approved test plan may be used for several similar tests, but a separate test record is required for each.

Benefits:

- Identifying and rectification of leakages

- Slight deformation and the material stresses redistributed.

- Ensure the integrity of weld repairs.

- Prevents failure of the system

Nitrogen purging

Nitrogen purging is an industry standard technique for the replacement of a hazardous or undesirable atmosphere with inert dry atmosphere. During the commissioning of a process plant, the replacement of air by purging with nitrogen is familiarly known as oxygen freeing or starts up purging. During a turnaround, the replacement of a hydrocarbon atmosphere with nitrogen is familiarly known as degassing or shutdown purging.

Benefits:

- Reduce turnaround schedules

- Improve operating efficiencies

- Implement the highest standards of site safety

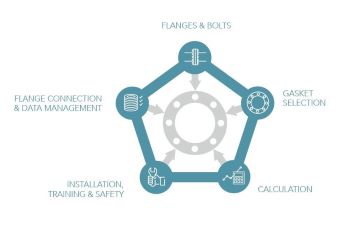

Flange Management

We provide engineering solutions to maintain the flange joint integrity in both onshore and offshore. We offering software based controlled bolting approach for commissioning, operations, turnarounds and shutdown application.

Controlled Method:

- Hydraulic/Manual Torquing

- Hydraulic Tensioning

Benefits:

- Maintains leak free joint

- Reduce preparation time

- Eliminate repetitive maintenance cost

- Assured reliability.

- Historical data collection

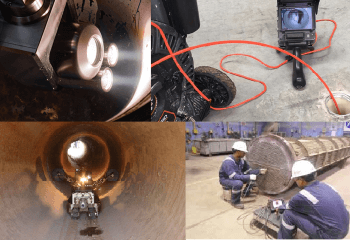

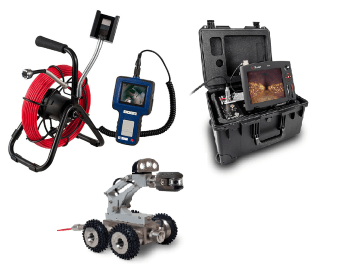

Video Inspection

We provide closed circuit video inspection/CCTV for pipeline, pressure vessel, Tank, Heat exchanger etc… The video /CCTV camera is able to navigate through bends and turn in the pipe, around minor objects, roots and debris while moving through the pipe.

We have the following cameras to perform the inspection,

- Push rod cameras

- Pan & Tilt Camera

- Robotic Camera/Crawler

Benefits:

- Cost effective

- Reduce system down time, labor and materials.

- Eliminate traditional excavation repair practices

- More accurate results

-

Commissioning

- Mechanical Commissioning

- Electrical & Instrumentation Commissioning

- Telecom Commissioning

- Other Technicians / Coordinator

- Instrument Calibration and Measurement Equipment

- Electrical Test Equipments

- Enviromental & Machine Monitoring Equipments

- Telecom & Network Test Equipments

- Third Party Inspection / Manpower supply services

Mechanical Commissioning

- Mechanical Manager / Lead

- Mechanical Engineer

- Mechanical Supervisor

- Mechanical Tech / Senior Technician

- Mechanical Assistants

- MC Coordinator / Expeditor

Electrical & Instrumentation Commissioning

- E & I Lead

- E & I Engineer

- E & I Supervisor

- E & I Tech / Senior Technician

- E & I Assistants

- Compex Inspector

- ATEX Inspector

Telecom Commissioning

- Telecom Lead

- Telecom Engineer

- Telecom Supervisor

- Telecom / Senior Technician

- Telecom Assistants

Instrument Calibration and Measurement Equipment

- Pressure Calibrator

- Temperature Calibrator

- mA Loop Power Calibrator

- Multi-Function Signal Calibrator

- HART & Foundation Fieldbus Communicator

- Decade Box

Electrical Test Equipments

- Primary current Injection Test Set

- SEcoundary Current Injection Test Set

- 3 Phase Current Injection Test Set

- Transformer Ratio and Polarity Tester

- Micro-Ohm Meter

- Analog / Digital Clamp Meter

- Phase Rotation Indicator

- Lux Tester

- 3 Phase power Logger

- RCD Tester

Enviromental & Machine Monitoring Equipments

- Vibration Meter

- Temperature & Humidity Meter

- Airflow Meter / Micromanometer

- Infrared Thermometer

- Tachometer

Third Party Inspection / Manpower supply services

- QA / QC Inspectors

- Welding Inspectors (AWS/CSWIP/PCN)

- Piping Inspector

- Piping Engineer

- Mechanical Inspector

- Mechanical Engineer

- Equipment Inspector

- Fabrication Expeditors

- E & I Inspector / Engineer

- API 510, 570, 653 Inspectors

- Painting / Coating Inspectors (NACE/BGAS)

Telecom & Network Test Equipments

- Cable IQ Qualification Tester

- Micro scanner Cable Verifier

- Audio Impedance Tester

- Sound Level Tester