- Radiography Testing (RT)

- Ultrasonic Testing (UT)

- Magnetic Particle Inspection

- Penetrant Testing

- Visual Testing

- Hardness Testing

- Concrete Testing

Radiography Testing

In radiography testing, the part to be inspected is placed between the radiation source and a piece of radiation sensitive film. The radiation source can either be an X-ray machine or a radioactive source. The radiation that passes through the part will expose the film and forms a shadow graph of the part. The film darkness (density) will vary with the amount of radiation reaching the film through the test object where darker areas indicate more exposure (higher radiation intensity) and lighter areas indicate less exposure (higher radiation intensity).

APPLICATIONS

- Weld inspection – Structural / Piping

- X-Rays, Gamma Rays (Iridium 192, Selenium 75, Cobalt 60)

- SCAR Radiography, Close Proximity Radiography

- Corrosion Under Insulation (CUI), Profile Radiography

- Casting / Forgings / Regulators

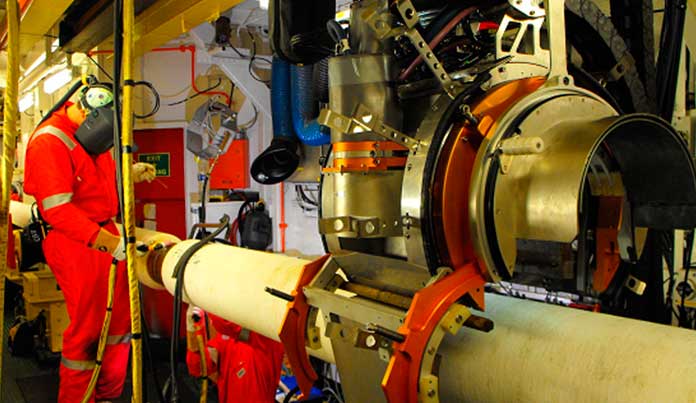

Ultrasonic Testing

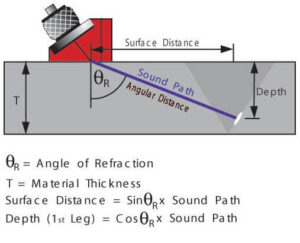

Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more. To illustrate the general inspection principle, a typical pulse/echo inspection configuration as illustrated below will be used.

APPLICATIONS

- Weld inspection – Structural / Piping

- Lamination Checking in Plates/Pipes

- Casting / Forgings / Valves

Magnetic Particle Inspection

Magnetic particle inspection (MPI) is a non destructive testing method used for defect detection in magnetic materials. MPI is fast and relatively easy to apply, and part surface preparation is not as critical as it is for some other NDT methods. These characteristics make MPI one of the most widely utilized non destructive testing methods.

APPLICATIONS

- Weld inspection – Structural / Piping

- Casting / Forgings / Valves

Penetrant Testing

Liquid penetrant inspection is a method that is used to reveal surface breaking flaws by bleed out of a coloured or fluorescent dye from the flaw. The technique is based on the ability of a liquid to be drawn into a “clean” surface breaking flaw by capillary action.

APPLICATIONS

- Weld inspection – Structural / Piping

- Casting / Forgings / Valves

Visual Testing (VT)

Visual testing can give a decent diagram of a vessel’s overall condition. First making sure the surface of a vessel is clean and well-lit, pressure vessel inspectors will examine any part of the vessel they can observe. They will look at things like any welded seams, such as those around appendages or along the length of the vessel’s shell.

APPLICATIONS

- good overview of a vessel’s general condition

- observe issues like cracking, corrosion, erosion or hydrogen blistering

Hardness Testing

Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation. More simply put, when using a fixed force (load)* and a given indenter, the smaller the indentation, the harder the material.

APPLICATIONS

- Verification of Hardness after PWHT

- Material Hardness verification after machining

Concrete Testing

Non Destructive Testing of concrete is vital to ensuring the strength and resilience of built structures. Field testing of concrete can occur during concrete installation or during investigative evaluations of installed concrete to determine strength qualities. ASTAR Testing provides a comprehensive suite of in-service concrete testing to ensure that the concrete suits the purpose.

Astar Testing and inspection expertise can provide assistance to clients in the process of understanding the condition of concrete structures. This includes

APPLICATIONS

- UPV test that provides crucial information about the integrity of the concrete structure and is typically used to identify the presence of voiding, cracking, honeycombing and sound concrete.

- Schmidt rebound hammer that measures the “Q value’’ at the in-situ concrete surface which is then converted via a calibration curve to determine the indicative concrete strength about the concrete surface.

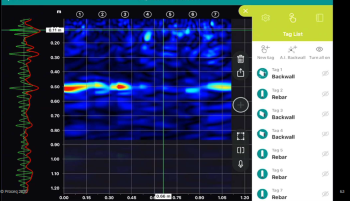

- Ground Penetrating Radar (GPR) that is used over large areas of concrete to map the internal steel reinforcement, identify voiding and/or quantify the likelihood of corrosion to the internal steel reinforcement.

- Ultrasonic Array Pulse equipment that can detect and locate defects in reinforced concrete such as honeycombing, voiding and the depth and extent of concrete delamination. This equipment is also used for the detection of embedment’s such as pipes, tendon ducts beneath a layer of rebar.